Fiber Optic Cable Installation

OVERVIEW

Fiber optic communication is the method of transmitting information from one place to another by sending pulses of infrared or visible light through an optical fiber. The current technologically advanced economic climate calls for fiber as the preferred medium over electrical cabling when high bandwidth, long distance, or immunity to electromagnetic interference is required. Fiber optic communication, when compared to other methods of data transfer, such as copper wire, has a vast number of benefits; from superior data transmission speeds to better transmission distance with minimal signal loss. When comparing the physical aspects of fiber optic cable to other mediums, fiber optic cables have a much lighter weight, a smaller diameter, and the ability to avoid corrosion and rust due to a non-metallic construction. These characteristics have placed fiber optics at the top of the list for communications in today’s world. However, it is important to note that the types of cabling – copper, fiber, or wireless – can differ according to the requirements stipulated. Depending on the project and cost, many networks combine all three types of cabling.

At VEST DISTINCTION, we are in the business of Fiber Optic Cable Installation. As competent contractors, we perform civil engineering works, fiber optic cable laying, set-up of cabinets and “wall boxes” or termination enclosures, fiber splicing, vertical (riser) and horizontal (floor) cabling, as well as jointing and testing of laid fiber optic cable components. In other words, we handle the planning, designing, implementation, and commissioning of fiber optic infrastructure, specializing in Outside plant (OSP) installations of fiber optic cables.

Essentially, OSP refers to all the equipment, cables, and infrastructure that are located outside of a building. Outside plant (OSP) installations of fiber optic cables can be much more diverse than premises installations. There are several types of outdoor fiber optic cables for communication systems. Built with outdoor elements in mind, each cable has differences in design and placement. For OSP and specifically for long-distance applications, we at VEST DISTINCTION recommend utilizing single-mode (SM) optical fiber cable as opposed to the multimode (MM) optical fiber cable. However, both these types of optical fibers have their attributes and are used as per the specific requirements, depending primarily on budget and applications.

OSP installations at VEST DISTINCTION fall into two broad categories: pole line aerial installation and underground cable installation. Each type of cable installation uses different procedures, tools, and even cables. A single route may include several types of installation, as the route may cross long distances; open fields, along paved rural or urban roads, crossroads, ravines, rivers or lakes, or, more likely, some combination of all of these. It could require buried cables, aerial cables, or underwater cables. The cable may be in a conduit, inner duct, or direct buried. Aerial cables may be self-supporting or lashed to a messenger. Some routes might even include crossing water, so the cable may be underwater or be lashed across a bridge with other cables.

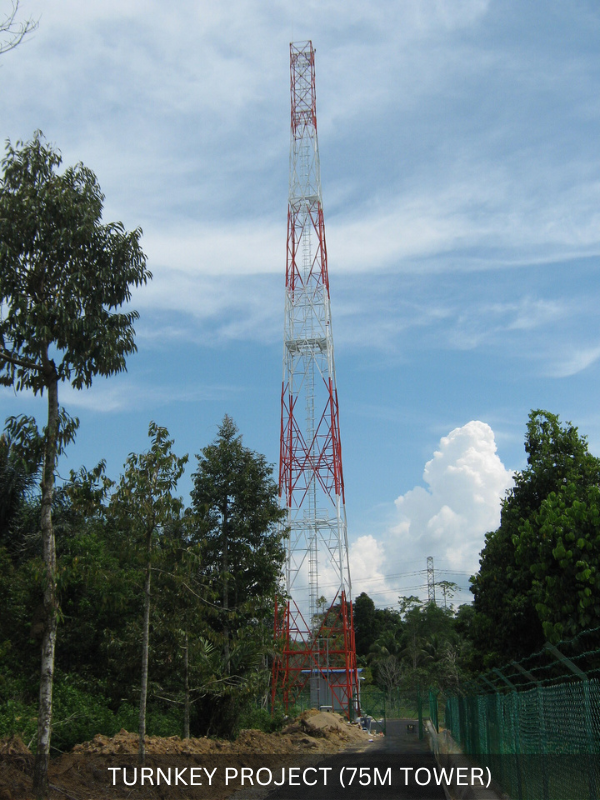

Pole line aerial installation of fiber optic refers to a kind of fiber optic cable that is designed and placed between poles by being lashed to a wire rope messenger strand with a small gauge wire.

Deploying fiber above ground on poles or towers removes the need for underground digging and is particularly useful when the ground is uneven, rocky, or both.

There are different aerial fiber cable methods of installation, depending on the project timeline and budget constraints. Our technicians adhere to strict specifications to avoid complications in the future. Essentially, there are four steps to installing aerial optical cables correctly: knowing the tools and materials, the installation hardware, careful planning, and installation methodology depending on site requirements.

An alternate method of cable installation is underground. In this context, fiber optic cable installation can be buried directly underground or placed into a buried duct.

For an underground installation, the optical fiber cables are either plowed in or buried in a trench. At VEST DISTINCTION, the methodology implemented to lay the cable is usually Open Trenching or Horizontal Directional Drilling (HDD), following the requirements of the project and the terrain of the route specified as well as a multitude of other considerations to be factored in.

Fiber optic cables can also be pulled through underground ducts, which protect the cables from harsh environments. Underground duct installation also provides an opportunity for future expansion without the need to dig. This is the most common practice in urban areas.

Underground placement is necessary and unavoidable in certain areas for various reasons such as nature and heritage conservation, natural obstacles, aesthetics, space, and safety. Placing cables underground has the added benefits of reducing transmission losses, aiding planning consent, and reducing the risk of service supply loss through extreme weather. Installation of Fiber Optic Cables For our fiber optic cable installation projects assigned to us by our clients, we adhere to all the requirements and have the customizations implemented according to the client’s specifications. Each project will have a set of specifications and conditions that require its own distinctive engineering and construction plan as every project is different depending on the expected outcome. A broad process flow would be as below:

At VEST DISTINCTION, we are in the business of Fiber Optic Cable Installation. As competent contractors, we perform civil engineering works, fiber optic cable laying, set-up of cabinets and “wall boxes” or termination enclosures, fiber splicing, vertical (riser) and horizontal (floor) cabling, as well as jointing and testing of laid fiber optic cable components. In other words, we handle the planning, designing, implementation, and commissioning of fiber optic infrastructure, specializing in Outside plant (OSP) installations of fiber optic cables.

Essentially, OSP refers to all the equipment, cables, and infrastructure that are located outside of a building. Outside plant (OSP) installations of fiber optic cables can be much more diverse than premises installations. There are several types of outdoor fiber optic cables for communication systems. Built with outdoor elements in mind, each cable has differences in design and placement. For OSP and specifically for long-distance applications, we at VEST DISTINCTION recommend utilizing single-mode (SM) optical fiber cable as opposed to the multimode (MM) optical fiber cable. However, both these types of optical fibers have their attributes and are used as per the specific requirements, depending primarily on budget and applications.

OSP installations at VEST DISTINCTION fall into two broad categories: pole line aerial installation and underground cable installation. Each type of cable installation uses different procedures, tools, and even cables. A single route may include several types of installation, as the route may cross long distances; open fields, along paved rural or urban roads, crossroads, ravines, rivers or lakes, or, more likely, some combination of all of these. It could require buried cables, aerial cables, or underwater cables. The cable may be in a conduit, inner duct, or direct buried. Aerial cables may be self-supporting or lashed to a messenger. Some routes might even include crossing water, so the cable may be underwater or be lashed across a bridge with other cables.

Pole line aerial installation of fiber optic refers to a kind of fiber optic cable that is designed and placed between poles by being lashed to a wire rope messenger strand with a small gauge wire.

Deploying fiber above ground on poles or towers removes the need for underground digging and is particularly useful when the ground is uneven, rocky, or both.

There are different aerial fiber cable methods of installation, depending on the project timeline and budget constraints. Our technicians adhere to strict specifications to avoid complications in the future. Essentially, there are four steps to installing aerial optical cables correctly: knowing the tools and materials, the installation hardware, careful planning, and installation methodology depending on site requirements.

An alternate method of cable installation is underground. In this context, fiber optic cable installation can be buried directly underground or placed into a buried duct.

For an underground installation, the optical fiber cables are either plowed in or buried in a trench. At VEST DISTINCTION, the methodology implemented to lay the cable is usually Open Trenching or Horizontal Directional Drilling (HDD), following the requirements of the project and the terrain of the route specified as well as a multitude of other considerations to be factored in.

Fiber optic cables can also be pulled through underground ducts, which protect the cables from harsh environments. Underground duct installation also provides an opportunity for future expansion without the need to dig. This is the most common practice in urban areas.

Underground placement is necessary and unavoidable in certain areas for various reasons such as nature and heritage conservation, natural obstacles, aesthetics, space, and safety. Placing cables underground has the added benefits of reducing transmission losses, aiding planning consent, and reducing the risk of service supply loss through extreme weather. Installation of Fiber Optic Cables For our fiber optic cable installation projects assigned to us by our clients, we adhere to all the requirements and have the customizations implemented according to the client’s specifications. Each project will have a set of specifications and conditions that require its own distinctive engineering and construction plan as every project is different depending on the expected outcome. A broad process flow would be as below:

- Route Survey and Inspection

- Planning and Mapping

- Civil Construction

- Testing and Commissioning

OUR VALUE PROPOSITION

ASEAN TELECOMMUNICATIONS INFRASTRUCTURE COMPANY BASED IN MALAYSIA

Our services are executed according to our client’s request with specific customizations catered for and strict safety guidelines adhered to. Vest Distinction strives to build infrastructure and provide services with economic value to our clients.

CLIENT-ORIENTED

INNOVATIVE & RESILIENT

QUALITY WORKMANSHIP

LET'S CONNECT

Company Email

LINKEDIN PROFILE

ENHANCING CONNECTIVITY THROUGH INFRASTRUCTURE

To enhance technology connectivity and improve quality of life by contributing to the development of rural areas and economic advancement through planning and building high-quality telecommunications infrastructures.

OUR

OBJECTIVE

OUR

OBJECTIVE

ENHANCING CONNECTIVITY THROUGH INFRASTRUCTURE

To enhance technology connectivity and improve quality of life by contributing to the development of rural areas and economic advancement through planning and building high-quality telecommunications infrastructures.